Manufacturing companies got wrecked by cyber-spies last year, Verizon report says

Cyber-spies backed by nation-states were behind a majority of data breaches experienced by manufacturing companies in 2016, according to Verizon’s newly published 2017 Data Breach Investigations Report. Verizon identified 620 data breach incidents in the manufacturing sector last year — of which 94 percent could be defined as “espionage” driven and attributable to “state-affiliated” actors. Roughly 91 percent of material stolen in these breaches had been categorized as “secret,” relating to proprietary information owned solely by the victim. Cybersecurity experts say hackers largely target the manufacturing industry in order to steal trade secrets, business plans and valuable intellectual property. Verizon defines cyber-espionage as incidents that include “unauthorized network or system access linked to state-affiliated actors and/or exhibiting the motive of espionage.” “When you make stuff, there is always someone else who wants to make it better, or at least cheaper. A great way to make something cheaper is to let […]

The post Manufacturing companies got wrecked by cyber-spies last year, Verizon report says appeared first on Cyberscoop.

Continue reading Manufacturing companies got wrecked by cyber-spies last year, Verizon report says

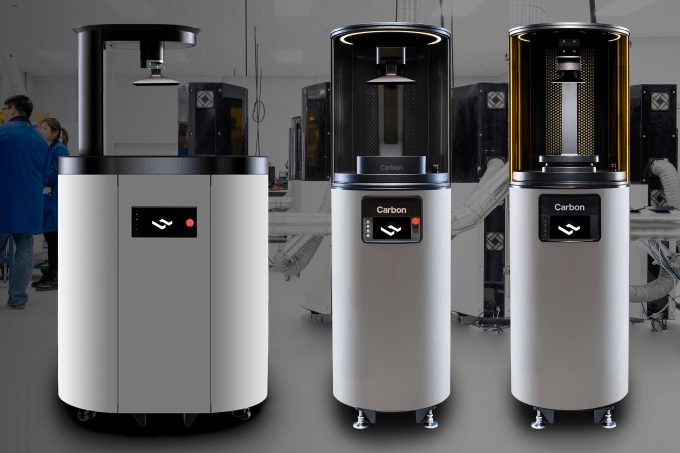

Additive manufacturing startup Carbon is on a mission to help manufacturers and designers cut their costs, waste less energy and materials while speeding up the time it takes to get from concept to product on the market. The company, which has raised $221 million in venture capital, is firing up a new service aimed at contract manufacturers, and other high volume manufacturing businesses,…

Additive manufacturing startup Carbon is on a mission to help manufacturers and designers cut their costs, waste less energy and materials while speeding up the time it takes to get from concept to product on the market. The company, which has raised $221 million in venture capital, is firing up a new service aimed at contract manufacturers, and other high volume manufacturing businesses,…